←

HSM

Innovative Motorized

Spindles

1

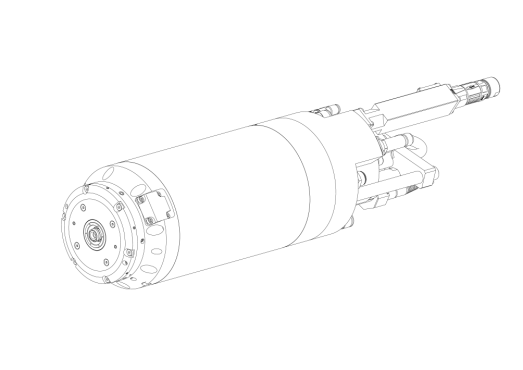

Grinding Spindles

High precision spindles for internal and external cylindrical grinding.

Low vibration amplitudes of HSTec spindles during the grinding process ensure excellent surface quality of the machined workpiece. Additionally, we offer dressing spindles designed for dressing and profiling of grinding wheels.

Options and functionalities:

- Rated power outputs from 1,5 kW to 150 kW

- Rotational speed up to 90000 rpm

- Manual or automatic tool clamping systems

- Tool interface: HSK, Grinding Arbor, customized solutions

- Hybrid or steel spindle bearings

- Bearing lubrication: grease or oil-air lubrication

- High-resolution speed and position sensor, incremental or absolute encoder

- Data Logger - Predictive maintenance with data acquisition and monitoring system

- Active balancing system

- Acoustic emission sensors

- Adaptive bearing preload

- Compensation of the spindle axial expansion

- Compatibility with all control devices and CNC machine programs

- Mounting dimensions and drive specifications according to customer request

| Spindle | ||||||

|---|---|---|---|---|---|---|

| Spindle | HSM050AA | HSM060AC | HSM060SB | HSM090SG | HSM132SB | HSE150SD |

| Pn (kW) | 4,5 | 15 | 10 | 70 | 31 | 70 |

| Mn (Nm) | 0,85 | 4,8 | 1,3 | 203 | 130 | 446 |

| nmax (rpm) | 50000 | 45000 | 75000 | 8000 | 7000 | 3000 |

| Spindle fitting Φ (mm) | 100 | 120 | 120 | 190 | 200 | 300 x 300 |

| Tool interface | HSK F40 | HSK C40 | HSK E25 | HSK A100 | HSK A80 | HSK A125 |

| Clamping system | Automatic clamping system (hydraulic) | Automatic clamping system (hydraulic) | Automatic clamping system (hydraulic) | Automatic clamping system (hydraulic) | Automatic clamping system (hydraulic) | Automatic clamping system (hydraulic) |

| Built-in motor | Asynchronous | Asynchronous | Synchronous | Synchronous | Synchronous | Synchronous |

| Spindle bearings | Hybrid bearings | Hybrid bearings | Hybrid bearings | Hybrid bearings | Hybrid bearings | Steel bearings |

| Lubrication system | Oil-air lubrication | Oil-air lubrication | Oil-air lubrication | Oil-air lubrication | Permanent grease lubrication | Permanent grease lubrication |

| Spindle cooling | Water with anti-corrosion agent | Water with anti-corrosion agent | Water with anti-corrosion agent | Water with anti-corrosion agent | Water with anti-corrosion agent | Water with anti-corrosion agent |

| Speed and position sensor | Incremental encoder | Incremental encoder | Incremental encoder | Incremental encoder | Incremental encoder | Absolute encoder |

| Active balancing system | Optional | Optional | Optional | Optional | Optional | Active balancing system integrated |

| Data Logger – Real time monitoring of bearing temperatures and vibration | Optional | Optional | Optional | Optional | Data Logger integrated | Optional |

| Sensor monitoring system | Temperature sensor

Clamping status monitoring |

Temperature sensor

Clamping status monitoring |

Temperature sensor

Clamping status monitoring |

Temperature sensor

Clamping status monitoring |

Temperature sensor

Acoustic emission sensor Clamping status monitoring |

Temperature sensor

Vibration sensor Clamping status monitoring |

2

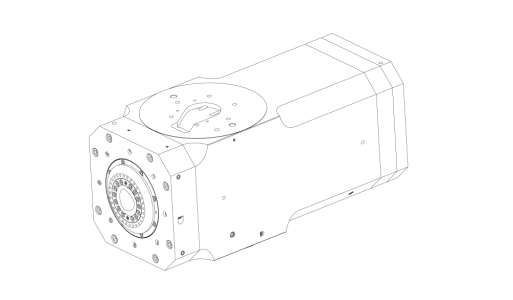

Milling Spindles

High-performance spindles for a variety of milling and boring applications.

Robust and reliable for high load capabilities. Designed for high efficiency CNC machine tools machining. Applicable for high speed cutting applications.

Options and functionalities:

- Rated power outputs up to 80 kW

- Rotational speed up to 28000 rpm

- Automatic tool clamping system and clamping status monitoring

- Hydraulic, pneumatic or electric release unit and rotary union up to 150 bar

- Tool interface: HSK, PSC (Capto), SK, BT, CAT, customized solutions

- Hybrid or steel spindle bearings

- Bearing lubrication: grease or oil-air lubrication

- High-resolution speed and position sensor, incremental or absolute encoder

- Data Logger - Predictive maintenance with data acquisition and monitoring system

- Active balancing system

- Compensation of the spindle axial expansion

- Compatibility with all control devices and CNC machine programs

- Mounting dimensions and drive specifications according to customer request

| Spindle | ||||||

|---|---|---|---|---|---|---|

| Spindle | HSM070SC | HSM100AB | HSM105AF | HSM105SC | HSM105SD | HSM112SB |

| Pn (kW) | 6,5 | 16 | 30 | 16 | 23 | 31 |

| Mn (Nm) | 6,5 | 64 | 97 | 28 | 130 | 130 |

| nmax (rpm) | 14000 | 8000 | 12000 | 20000 | 4000 | 2000 |

| Spindle fitting Φ (mm) | 140 | 208 | 210 | 200 | 220 | 215 |

| Tool interface | HSK A63 | Custom tool interface | SK 40 | Custom tool interface | HSK A80 | HSK A80 |

| Clamping system | Automatic clamping system (hydraulic) | Custom manual clamping system | Automatic clamping system (hydraulic) | Automatic tool clamping system (pneumatic) | Automatic clamping system (hydraulic) | Automatic clamping system (hydraulic) |

| Built-in motor | Synchronous | Asynchronous | Asynchronous | Synchronous | Synchronous | Synchronous |

| Spindle bearings | Hybrid bearings | Hybrid bearings | Hybrid bearings | Hybrid bearings | Steel bearings | Steel bearings |

| Lubrication system | Permanent grease lubrication | Permanent grease lubrication | Permanent grease lubrication | Oil-air lubrication | Permanent grease lubrication | Permanent grease lubrication |

| Spindle cooling | Water with anti-corrosion agent | Water with anti-corrosion agent | Water with anti-corrosion agent | Water with anti-corrosion agent | Water with anti-corrosion agent | Water with anti-corrosion agent |

| Speed and position sensor | Incremental encoder | Absolute encoder w. Sin-Cos Incr. signal | Incremental encoder | Incremental encoder | Incremental encoder | Incremental encoder |

| Rotary union for tool cooling | Optional | - | Optional | Optional | Rotary union integrated | Rotary union integrated |

| Active balancing system | Optional | Optional | Optional | Active balancing system integrated | Optional | Optional |

| Data Logger – Real time monitoring of bearing temperatures and vibration | Optional | Optional | Data Logger integrated | Optional | Optional | Optional |

| Sensor monitoring system | Temperature sensor

Clamping status monitoring |

Temperature sensor | Temperature sensor

Clamping status monitoring |

Temperature sensor

Clamping status monitoring |

Temperature sensor

Clamping status monitoring |

Temperature sensor

Clamping status monitoring |

3

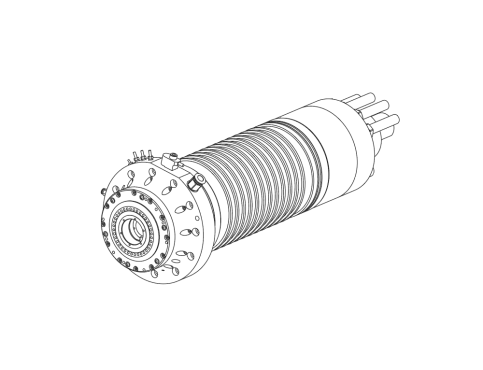

Lathe Spindles

High torque spindles designed for turning applications.

Custom made special purpose spindles for demanding turning operations. Powerful B-axis milling spindles for CNC lathe machines.

Options and functionalities:

- Maximum torque outputs up to 500 Nm

- Rotational speed up to 10000 rpm

- Automatic tool clamping system and clamping status monitoring

- Workpiece clamping with a variety of different chucks

- Hybrid or steel spindle bearings

- Bearing lubrication: grease or oil-air lubrication

- High-resolution speed and position sensor, incremental or absolute encoder

- Data Logger - Predictive maintenance with data acquisition and monitoring system

- Compatibility with all control devices and CNC machine programs

- Mounting dimensions and drive specifications according to customer request

4

Spindles for special purpose and robot machining

Lightweight spindles and custom design suitable for mounting on industrial robots.

Custom made for various operations, such as balance and force test stands, turret heads.

Mounting dimensions and drive specifications according to customer request.

| Spindle | ||||||

|---|---|---|---|---|---|---|

| Spindle | HSE070AA spindle for robotic machining | HSE105SC spindle for robotic machining | HSM100SB spindle for Friction Stir Welding process (FSW) | HSE130SE high speed motor for test stands | HSS105SE high speed motor for various applications | HSS180AG high torque motor for various applications |

| Pn (kW) | 6,3 | 30 | 24 | 100 | 26 | 100 |

| Mn (Nm) | 5 | 42 | 66 | 48 | 60 | 1872 |

| nmax (rpm) | 12000 | 18000 | 6500 | 20000 | 15000 | 980 |

| Spindle fitting (mm) | 140 x 123 | 197 x 170 | Φ 230 | 600 x 274 | 525 x 220 | Φ 350 |

| Tool interface | HSK C40 | HSK A63 | HSK A63 | Custom shaft interface | Custom shaft interface | Custom shaft interface |

| Clamping system | Manual clamping system | Automatic clamping system (pneumatic) | Automatic clamping system (pneumatic) | - | - | - |

| Built-in motor | Asynchronous | Synchronous | Synchronous | Synchronous | Synchronous | Asynchronous |

| Spindle bearings | Steel bearings | Hybrid bearings | Steel bearings | Hybrid bearings | Steel bearings | Steel bearings |

| Lubrication system | Permanent grease lubrication | Oil-air lubrication | Permanent grease lubrication | Oil-air lubrication | Permanent grease lubrication | Permanent grease lubrication |

| Spindle cooling | Water with anti-corrosion agent | Water with anti-corrosion agent | Water with anti-corrosion agent | Water with anti-corrosion agent Rotor cold air cooling |

Water with anti-corrosion agent | Water with anti-corrosion agent |

| Speed and position sensor | Induction sensor for speed control | Incremental encoder | Incremental encoder | Incremental encoder | Incremental encoder | Incremental encoder |

| Data Logger – Real time monitoring of bearing temperatures and vibration | Optional | Optional | Optional | Optional | Optional | Optional |

| Integrated sensors | Temperature sensor | Temperature sensor | Temperature sensor Integrated load cells |

Temperature sensor | Temperature sensor | Temperature sensor |

5

Direct drives

Designed for top performance and custom made for special applications.

Customized motors for demanding applications. Two-axis milling heads. Linear drive units. One and two axis rotary tables. Direct drive high torque motors with absolute measuring encoder system.