←

Machine Tending Robots

Case Study

Along with technological progress, traditional methods in the manufacturing process have been challenged by safety standards improvements and requirements, as well as by the decline of the qualified workforce. This is especially evident in CNC machine tool shops where the workpiece loading snd unloading is done by machine operators. This often tedious, repetitive, and sometimes dangerous procedure resulted in a downtrend of interest in such job positions among young people.

The same problem occurs on most production lines where numerous operators load, unload, sort, move and visually control manufactured pieces. There is, of course, the issue of accuracy and repeatability when we compare the human eye to the robot eye.

The introduction of industrial robots in the manufacturing process is not only a question of increased profit anymore; it is becoming essential due to a lack of skilled workers and a lack of interest in such jobs in general.

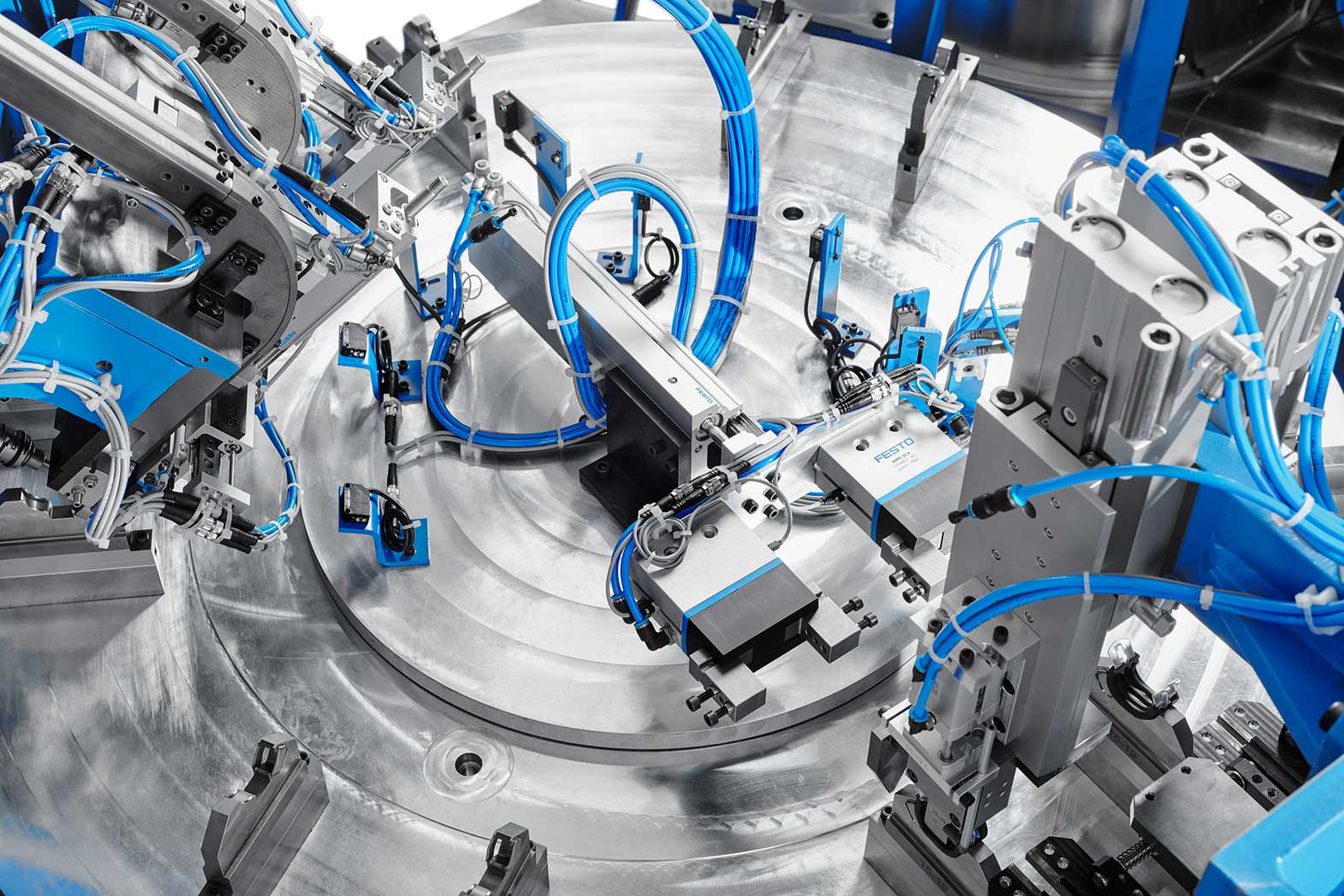

The requirements of the modern manufacturing process are safety, productivity, and promptness of robot automation integration into manufacturing lines. The robots must be ready for repetitive, accurate, and safe operations, and able to see, analyze and learn. The integration of robots in the manufacturing process must be done in as short a period as possible because the production must be continuous.

HSTec has been at the heart of the action for decades now, doing its best to solve every issue in production lines (with engineering, automation, and productivity improvement) for our clients and partners. We offer turnkey solutions encompassing the entire process: the scanning of the actual manufacturing process, development and design of the whole solution, engineering and assembly, automation, and adjustment with the process. Advanced solutions, such as 2D/3D machine vision control and machine learning, can be added as a part of a robot machine tending procedure.

We also offer flexible machine tending robot cells, ready for quick and simple installation and integration with the CNC machine tool (suitable for all milling machines and lathes).

Our expertise in robot automation and years of successful robot integrations in many different production plants are the main evidence that industrial robot automation has many advantages. These are higher quality and reliability, maximum productivity and safety, reduced production costs, future predictions based on machine learning, improved connectivity and communication with other plant devices, and ERP systems.